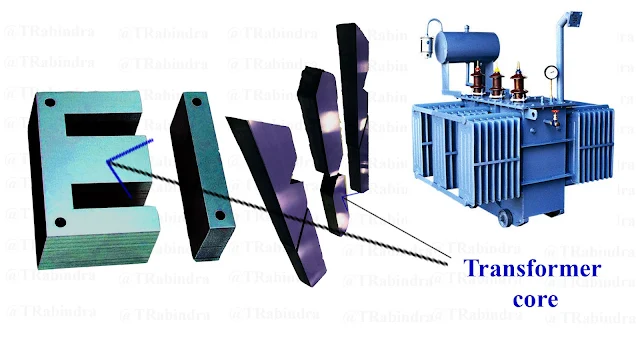

Transformer Core

Transformer core is defined as the center of transformer that supports winding and provides low reluctance magnetic path to transfer magnetic flux from primary to secondary winding. It is the most important parts of the transformer and made from highly permeable material. It is made up of laminated soft iron material to reduce eddy current loss and hysteresis loss.

Nowadays, laminated sheets are used to minimize eddy current loss and CRGO (Cold Rolled Grain Oriented) steel to minimize hysteresis loss. These sheets are separated by insulating materials and its composition depends on level of voltage, current and frequency.

Function of Laminated Core in Transformer

The main function of the laminated core in transformer is to support both winding and to provide low reluctance path for energy transformation by flowing magnetic flux through it. It reduces losses due to flux leakage.

Properties of Transformer Core

The property of the material of transformer core has been listed below.

- low Magnetic Reluctance

- Good Mechanical Strength

- Low Magnetostriction

- High Permiability

Working of Transformer Core

The working of transformer core is very simple. When alternating current passing through the primary winding of the transformer, varying magnetic flux is induced. This varying magnetic flux circulates in the transformer core and is transferred to the secondary winding through the core.

According to faraday’s law of electro-magnetic induction, this change in flux induces electro-magnetic force (emf) in the secondary winding. Secondary winding is linked to the primary winding of the transformer through the core of the transformer. This is also called mutual induction.

Construction of Transformer Core

Its construction is very simple in aspect of design and easy to install. It is consists of a laminated having two winding wound on it. The vertical part of the transformer core on which winding is mounted is known as limbs and the vertical part that connects the limb is known as yoke.

The individual laminated sheets are stamped and punched out from the larger steel sheets and formed into strips of thin steel resembling the letters “E”, “L”, “U” and “I”. These stamped sheets are connected together to form required shape of the transformer core. There are four types of construction made in transformer core which has listed below.

- E-I

- E-E

- L-L

- U-I

Types of Transformer Core

Depending upon the arrangement of primary and secondary winding transformer core are classified into two types which are listed below.

- Core type Arrangement

- Shell type Arrangement

1) Core Type Arrangement

In core type arrangement, primary and secondary winding are wound outside of the magnetic circuit in such a way that it surrounds the core ring. The low voltage winding is placed closer to the core to reduce insulation and high voltage winding around low voltage winding.

a) Core type arrangement in single phase transformer

This type of arrangement consists of a rectangular core with two limbs and two yokes. The primary and secondary winding are split into two parts that are placed on each limbs. The cross-sectional area of the limbs and yokes are kept identical. The leakage flux is higher due to the disturbed nature of the winding.

b) Core type arrangement in three phase transformer

This type of arrangement consists of three limbs and two yokes. Each phase is wound around each limbs. Each winding is divided into sub-sections in which low and high voltage winding sub-sections are alternatively placed on each limb per phase. The algebraic sum of magnetic fluxes induced by the phases remains zero at any time of instant.

2) Shell Type Arrangement

In shell type arrangement, primary and secondary winding are wound inside the magnetic circuit. Outer limbs surrounds the winding. Each winding is divided into sub-sections in which low and high voltage winding sub-sections are alternatively placed on the each limb in the form of a sandwich. Hence, it is also called sandwich and disc winding.

a) Shell type single phase transformer

In shell type three phase transformer, there are three limbs and two yokes and winding are wound around the central limb. Each winding is divided into sub-sections in which low and high voltage winding sub-sections are alternatively placed on each limb per phase.

The magnetic flux flows through the auxiliary limbs. The auxiliary limbs and yokes needed to be half of the cross section of the central limb. It is preferred as is more economical than other.

b) Shell type three phase transformer

In shell type three phase transformer, there are five limbs and four yokes. Winding are wound on the inner three limbs. Each winding is divided into sub-sections in which low and high voltage winding sub-sections are alternatively placed on each limb per phase. One set of primary and secondary winding are placed per phase per limb. This type of construction can help in reducing the height of the core.